What are plasticizers? What are they used for? How do they work? Are they harmful?

And, what adhesives can you use with them?

Plasticizers are colorless and odorless liquids that are added to a raw polymer, such as rubber or plastic, to soften the material. They increase the flexibility and elasticity of the product, making it easier to shape and mold, as well as reducing friction on the surface. Plasticizers help the material to not break easily in cold temperatures, increasing the durability all around. These features allow the material to be used in a wide range of applications. Without them, the material would be hard and rigid, and not so easy to shape.

What are the common types of plasticizers?

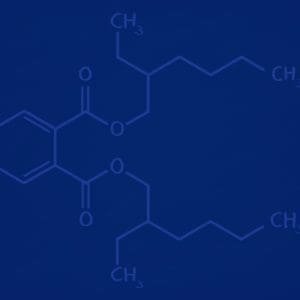

- Phthalates

- Dicarbonates

- Phosphates

- Polyesters

- Esters

- Citrates

- Bio-based Plasticizers

- Chlorinated Paraffins

The main material that plasticizers are used in, is PVC (polyvinyl chloride), also known as vinyl. However, they are also used in materials such as PETs, acrylics, polyurethanes, polystyrene, polyolefins, coatings, rubbers, concrete, stucco, adhesives and sealants, and even paints and printing inks.

These additives are used in many industries including the wall coverings, flooring and seating industries. Some of the other industries they’re used in include architecture, lifestyle, sports, advertising, defense, mining, food & agriculture, and transportation. Plasticizers are used in many applications across these industries, from wire and cable insulation, flexible hoses, roofing membranes and automotive interior trim, to medical devices, signage, films and fabrics, to footwear, luggage, tents and outdoor furniture, and a whole variety of other household and industrial applications.

Are they harmful? For the most part, no, as they are pretty tightly regulated by government organizations.

What does all this have to do with adhesives? Well, plasticizers are bad news for adhesives. They can leach out into or onto the surface to which it’s bonded, and can make the adhesive very sticky, or can cause the adhesive to lose its bonding characteristics. This could lead to less flexibility, embrittlement, cracking or even adhesive failure.

What causes plasticizers to leach out? It could be incompatibility between the polymer and the plasticizer, or it could be another factor such as temperature or humidity change, weathering, or mechanical stress. Sometimes even an adhesive could cause the leaching, if the adhesive contains very abrasive components or strong solvents.

So, how do you prevent plasticizers from leaching out? You need make sure the plasticizer is compatible with the material you’re mixing it with, that it’s compatible with the substrates you’re bonding it to, and that you’re using a plasticizer-resistant adhesive.

Curious to learn more about plasticizers, or what adhesive is compatible with your application? Contact us and let us know your application and the substrates you’re bonding – we would love to guide you through to adhesive success!