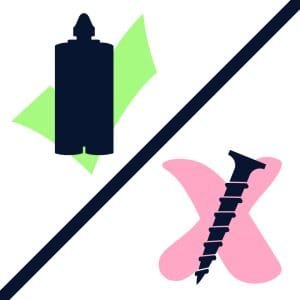

Structural Adhesives vs Mechanical Fasteners

Structural adhesives are a powerful alternative to traditional mechanical fasteners. They offer superior strength, cost-effectiveness, and ease of use in manufacturing processes. Unlike mechanical fasteners, which only distribute holding power at the point of attachment, structural adhesives distribute holding power along the entire bond line, resulting in a stronger bond.

In addition to their superior strength, structural adhesives offer a range of benefits over traditional methods such as welding or mechanical fastening. They’re a more cost-effective solution, with a faster application process that can save time and increase production. Furthermore, the use of structural adhesives requires less skill, making it accessible to a wider range of users.

Structural adhesives are widely used in a variety of industries, including trailer and fiberglass manufacturing, among others. If you’re looking to improve your manufacturing process and increase the strength and reliability of your bonds, consider

switching to structural adhesives. Contact us to learn more about the benefits of structural adhesives and how they can

help improve your manufacturing process.