How do Moisture-Cure Urethanes Work?

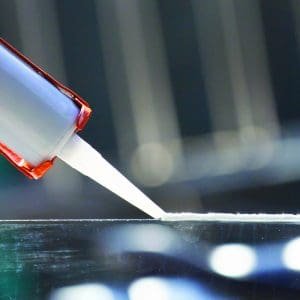

Moisture-cure urethanes are single-part structural polyurethane reactive adhesives that require moisture to cure. They are known as “reactive” adhesives because they need a catalyst, in this case exposure to moisture, to begin the chemical reaction of curing. Dispensing equipment needs to be completely sealed so that no moisture can get in, to prevent the adhesive from curing inside the equipment.

Moisture-cure urethanes cure using the residual moisture in the air and on the surfaces of the substrates they’re bonding, and will foam slightly while curing. They can be applied in most environments, but require 40% to 70% humidity for the reaction to take place. For environments with very low humidity, or in applications where the substrates are impermeable to moisture, moisture can be added to the bond line during assembly.

These adhesives provide exceptional bond strength, yet remain elastic and flexible once cured, and will expand and contract with the natural movement of the substrates. With their cured flexibility, moisture-cure urethanes are often used in applications where substrates have differing elongation under loads, or where substrates have differing thermal coefficients of expansion to be joined. Moisture-cure adhesives are used to bond substrates in many applications across most industries. They can even bond difficult-to-bond substrates such as metals and plastics, although they shouldn’t be used to bond substrates containing polyethylene or polypropylene.

Interested to learn more about these adhesives and how you can use them in your application? Contact us, we would love to chat structural adhesives with you!