What all is involved in adhesive testing, and why is it important?

Adhesive testing is used to see how an adhesive will perform in and under stress, and to test the strength, reliability and durability of the adhesive over time. It is used to test the adhesion level and compatibility of an adhesive with the substrates being bonded, and to determine the strength of the bond, to determine whether the adhesive is suited for a particular application. Adhesive testing aids in the selection of adhesive systems and materials for an application and is used to optimized formulation and processes, as well as providing assurance against bond failure. The effects of temperatures and environmental conditions on adhesive bonds and joints are also evaluated – testing can be performed hot, wet or dry at ambient, elevated or reduced temperatures.

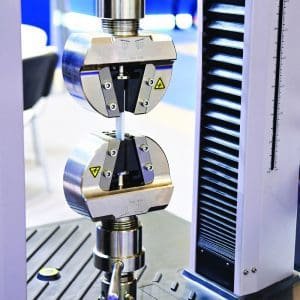

How do you test the strength of adhesive? There are many different tests that are used in the evaluation of adhesives, not just strength tests, and tests are often done in accordance with ASTM adhesive testing standards.

You can learn more about tensile, shear and peel strength in this adhesive strength tests blog, but here is a quick overview of adhesive testing methods:

- Shear Strength

- Measures the ability of a bonded joint to resist creep or slippage.

- Tensile Strength

- Measures the force (or load) required to break a bonded joint.

- Peel Strength

- Measures the force needed to “peel” an adhesive tape from any given surface, whether flexible, smooth, or rigid.

- Elongation

- Measures the percentage in which a tape can be stretched just before breaking.

- Tack Strength

- Measures the ability of an adhesive to instantaneously form a bond to a substrate using light contact pressure.

- Green Strength

- Measures the early development of bond strength immediately after the bond is made.

- Creep Test

- Measures the heat resistance of a bonded joint.

- Plasticizer Resistance

- Measures the compatibility of an adhesive with plasticizers.

- Cohesive Strength

- Measures the force required to pull apart the adhesion that joins the surfaces.

- Impact Resistance

- Measures the strength of a bonded joint under load.

- Viscosity

- Measures the ability of an adhesive to flow.

- Fracture Toughness

- Measures the resistance of a bonded joint to crack initiation and growth, under tensile and shear loading conditions.

- Fatigue

- Measures the localized stress state of a bonded joint.

- Accelerated Aging

- Tests the performance of adhesive bonds under long-term exposure to environmental conditions such as temperature, moisture, UV light or vibrations.

There are many different factors to take into consideration when conducting adhesive testing.

What substrates are being bonded? This should help determine what type of adhesion you need, whether it be mechanical, diffusion, chemical, acid-base, wetting or electrostatic. Always consult the adhesive manufacturers product information sheets prior to testing, to find out cure times and other information that may impact test results. Ensure the adhesive is applied correctly, as the adhesive thickness can impact bond strength. The adhesive must be allowed to fully cure before testing (unless it’s a tack or green strength test!).

Take into consideration the test environment. Are the substrates being bonded at a temperature and environment that is similar to real world applications? Moisture can decrease the ability of some adhesives to bear prolonged stress, especially at slightly elevated temperatures. Exposure to more than one environment at a time, such as heat and moisture, could cause the bond to degrade much faster than when exposed to a single environment, as the combination of environments could accelerate the degrading effects. Also, mechanical stress can increase the effect of the environment on the adhesive joint. Bear in mind that the strength values determined by short-term tests do not always accurately portray the adhesives performance during continuous environmental exposure, so long-term testing or accelerated testing may be needed.

Ensure substrates are clean and adequate surface prep has been done prior to testing, so that there’s nothing on the surface of the substrates that could interfere with test results. If the adhesive is exposed to any condition or chemical that might degrade it prior to testing, the test may not provide accurate results.

Test failure can occur due to incorrect resin or additive selection, inadequate amounts of adhesive used or length of cure, contamination issues and cross-contamination issues, substrate issues or even formulation issues. If the adhesive and/or cohesive strength of the coating system exceeds the bond of the loading fixture to the coated surface, the adhesive could fail. If a bond failure occurs at an applied load greater than the pass/fail criteria there is no need to retest, but if a bond failure occurs below the acceptance criteria then it may need to be retested.

Do you need help finding the right adhesive for your application? We would love do some testing for you and provide our recommendations – just let us know your application and the substrates you’re bonding!

And if you just want to brush up on your adhesive terminology after reading this blog, check out our adhesive terms glossary!